Introduction:

Battery technology has witnessed significant advancements in recent years, with the development of high-energy-density batteries being at the forefront. Among the various components that contribute to the performance of a battery, the electrolyte plays a crucial role. The electrolyte serves as the medium through which ions are transferred between the anode and cathode, facilitating the electrochemical reactions that generate electrical energy. This article explores the two main approaches to enhancing battery electrolyte performance: high-concentration formulations and the use of additives.

High-Concentration Electrolyte Formulations:

One approach to improve battery performance is through the use of high-concentration electrolyte formulations. These formulations involve increasing the concentration of active ingredients, such as lithium salts, in the electrolyte solution. The primary advantage of high-concentration electrolytes is the potential for higher energy density, as a greater number of ions are available for the electrochemical reactions.

However, there are challenges associated with high-concentration electrolytes. One of the main concerns is the increased viscosity of the electrolyte solution, which can hinder ion transport and lead to higher internal resistance. This, in turn, can result in reduced battery performance and lifespan. Moreover, the higher concentration of active ingredients can also increase the risk of dendrite formation, which can lead to short-circuiting and battery failure.

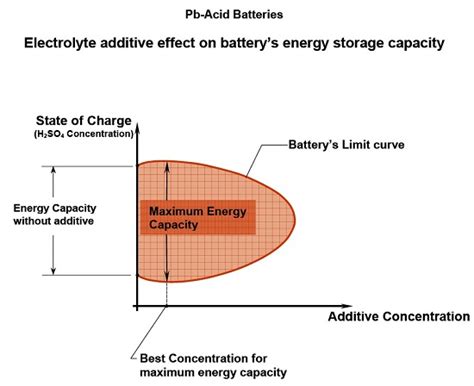

Additive Effects in Electrolyte Formulations:

Another approach to enhancing battery electrolyte performance is the use of additives. These additives can improve various aspects of the electrolyte, such as ionic conductivity, stability, and cycle life. Some common types of additives include:

1. Dendrite Inhibitors: These additives help prevent the growth of metallic lithium dendrites, which can cause short-circuiting and battery failure. Examples of dendrite inhibitors include poly(ethylene glycol) (PEG) and hexafluorophosphate (HFP).

2. Conductivity Enhancers: These additives improve the ionic conductivity of the electrolyte, thereby reducing internal resistance and improving battery performance. Common conductivity enhancers include tetraethyl orthosilicate (TEOS) and poly(vinyl pyrrolidone) (PVP).

3. Electrolyte Stabilizers: These additives enhance the stability of the electrolyte against thermal and chemical degradation. Examples include sulfuric acid and hexafluoroisopropanol (HFIP).

Comparative Analysis:

When comparing high-concentration electrolyte formulations with additive effects, it is essential to consider several factors:

1. Energy Density: High-concentration electrolytes have the potential for higher energy density, while additives can provide incremental improvements in energy density.

2. Cost: High-concentration electrolytes may require more expensive raw materials, whereas additives are generally more cost-effective.

3. Performance: Additive effects can significantly improve various aspects of battery performance, such as cycle life and conductivity, without the need for high-concentration formulations.

4. Safety: High-concentration electrolytes may pose higher safety risks due to increased dendrite formation, while additives can help mitigate these risks.

Conclusion:

Both high-concentration electrolyte formulations and additive effects offer promising approaches to enhance battery electrolyte performance. While high-concentration electrolytes may offer higher energy density, the use of additives can provide more comprehensive improvements in various aspects of battery performance. Ultimately, the choice between these approaches depends on specific application requirements, cost considerations, and safety concerns. As battery technology continues to evolve, further research and development efforts are necessary to optimize electrolyte formulations and ensure the long-term success of high-energy-density batteries.