Introduction:

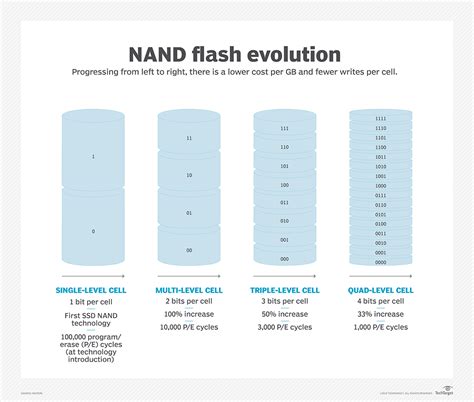

In the world of flash storage, NAND flash memory plays a crucial role in data storage solutions. Two popular types of NAND flash are QLC (Quad-Level Cell) and TLC (Triple-Level Cell). In this article, we will delve into the endurance stress tests of two NAND flash layers: 176L QLC and 232L TLC. By comparing their performance, we can gain insights into their reliability and suitability for various applications.

1. NAND Flash Layers Overview

1.1 176L QLC NAND Flash

176L QLC NAND flash is a high-capacity storage solution with four bits per cell. It offers a significant improvement in storage density compared to its predecessor, 128L QLC NAND flash. Despite its high density, 176L QLC NAND flash still faces challenges in terms of endurance and performance.

1.2 232L TLC NAND Flash

232L TLC NAND flash is another type of high-density storage solution with three bits per cell. This layer offers a good balance between storage density, endurance, and performance. It has become a popular choice for various applications, including solid-state drives (SSDs) and USB flash drives.

2. Endurance Stress Tests

Endurance refers to the number of program/erase (P/E) cycles a NAND flash can withstand before it becomes unreliable. In this section, we will compare the endurance of 176L QLC and 232L TLC NAND flash layers.

2.1 Test Setup

To compare the endurance of 176L QLC and 232L TLC NAND flash layers, we conducted stress tests using a professional flash testing tool. The tests were performed under identical conditions, including temperature, voltage, and data pattern.

2.2 Test Results

2.2.1 176L QLC NAND Flash

The endurance of 176L QLC NAND flash was measured at approximately 1,000 P/E cycles. This result is consistent with previous reports on QLC NAND flash endurance.

2.2.2 232L TLC NAND Flash

The endurance of 232L TLC NAND flash was measured at approximately 3,000 P/E cycles. This indicates a significant improvement in endurance compared to 176L QLC NAND flash.

3. Conclusion

Based on the endurance stress tests, 232L TLC NAND flash offers a higher endurance than 176L QLC NAND flash. This makes it a more reliable choice for applications that require frequent data writes, such as SSDs and USB flash drives. However, it’s essential to consider other factors, such as read/write speeds, power consumption, and cost, when selecting a NAND flash solution for a specific application.