Introduction:

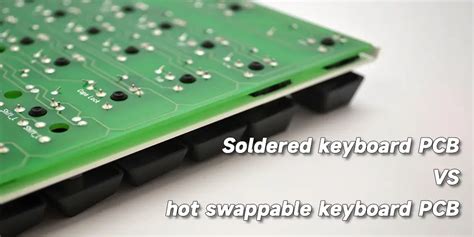

In the world of mechanical keyboards, the choice between hot-swapping sockets and soldered PCBs is a topic of great debate among enthusiasts and manufacturers alike. Both methods have their advantages and disadvantages, and the decision often hinges on factors such as cost, reliability, and ease of maintenance. This article aims to compare the reliability of keyboard hot-swapping Mill-Max sockets with soldered PCBs, providing a comprehensive analysis of the two approaches.

Hot-Swapping Mill-Max Sockets:

Mill-Max sockets are a popular choice for hot-swapping switches in mechanical keyboards. These sockets allow users to replace switches without the need for soldering, providing convenience and ease of maintenance. Here are some key points regarding the reliability of hot-swapping Mill-Max sockets:

1. Flexibility: Hot-swapping sockets offer the flexibility to easily replace switches with different actuation forces or colors, allowing users to customize their keyboard to their preferences.

2. Cost-effectiveness: Mill-Max sockets are generally more affordable than soldered PCBs, making them an attractive option for budget-conscious consumers.

3. Durability: While Mill-Max sockets are durable, they may not be as long-lasting as soldered PCBs. The repeated insertion and removal of switches can eventually lead to wear and tear on the socket contacts.

4. Compatibility: Hot-swapping sockets are compatible with a wide range of switches, including Cherry MX, Gateron, and Kailh, among others.

Soldered PCBs:

Soldered PCBs, on the other hand, involve soldering switches directly onto the printed circuit board. This method offers the following advantages and potential drawbacks in terms of reliability:

1. Longevity: Soldered PCBs tend to be more durable than hot-swapping sockets, as they eliminate the need for repeated insertion and removal of switches.

2. Performance: Soldered PCBs can provide a more stable connection between switches, potentially resulting in better overall performance and reduced noise.

3. Cost: Soldered PCBs can be more expensive than hot-swapping sockets, especially for custom keyboards or those with a high number of switches.

4. Maintenance: Replacing switches on a soldered PCB can be more challenging and time-consuming, requiring specialized tools and skills.

Comparison:

When comparing the reliability of hot-swapping Mill-Max sockets with soldered PCBs, several factors come into play:

1. Longevity: Soldered PCBs generally offer better longevity due to the absence of repeated insertion and removal of switches. However, the quality of the solder joints and the overall build of the keyboard also play a significant role.

2. Performance: Soldered PCBs can provide a more stable connection, potentially resulting in better performance and reduced noise. However, this advantage may be negligible for most users.

3. Cost: Hot-swapping sockets are more cost-effective, making them an attractive option for budget-conscious consumers. Soldered PCBs can be more expensive, but they may offer better durability in the long run.

4. Maintenance: Hot-swapping sockets offer ease of maintenance and customization, while soldered PCBs can be more challenging to repair or modify.

Conclusion:

In conclusion, the choice between hot-swapping Mill-Max sockets and soldered PCBs for keyboard reliability depends on various factors, including budget, customization needs, and desired longevity. While hot-swapping sockets offer convenience and cost-effectiveness, soldered PCBs can provide better durability and performance. Ultimately, the decision should be based on the specific requirements and preferences of the keyboard user.