In the ever-evolving world of technology, the advent of 4D printing has opened up a new realm of possibilities. This innovative printing technique has now been utilized to shape-memory alloys, leading to the creation of self-repairing devices. This article delves into the fascinating world of 4D printing and its potential applications in the development of self-healing technologies.

What is 4D Printing?

4D printing is an extension of 3D printing that allows objects to change shape over time or in response to certain stimuli. The “4th dimension” refers to the ability of the printed object to change shape, which is not possible with traditional 3D printing. This technology has the potential to revolutionize various industries, including aerospace, automotive, and healthcare.

Shape-Memory Alloys: The Key to Self-Repairing Devices

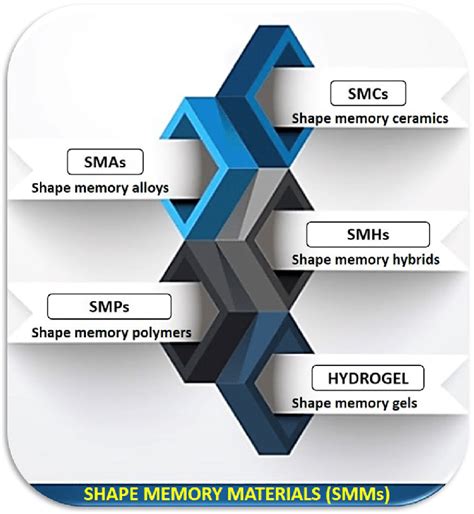

Shape-memory alloys (SMAs) are a class of materials that can return to their original shape after being deformed. This property makes them highly desirable for applications in self-repairing devices. When combined with 4D printing technology, SMAs can be used to create objects that can heal themselves after damage.

The process involves printing an SMA-based material in a specific shape. When the material is exposed to heat or stress, it undergoes a phase transition and returns to its original shape. This self-healing capability can be harnessed to create devices that can repair minor damage without the need for external intervention.

Applications of 4D Printing with Shape-Memory Alloys

1. Aerospace: In the aerospace industry, 4D printing with shape-memory alloys can be used to create lightweight, self-repairing components for aircraft. This technology can improve the durability and lifespan of aircraft, leading to reduced maintenance costs and increased safety.

2. Automotive: The automotive industry can benefit from 4D printing with shape-memory alloys by creating self-repairing car parts. This can lead to improved fuel efficiency, reduced emissions, and enhanced safety features.

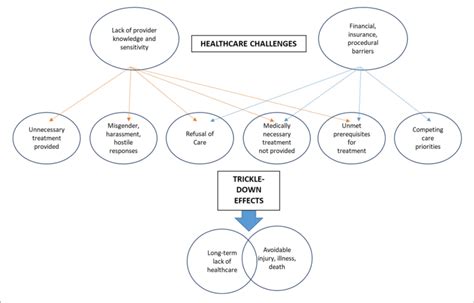

3. Healthcare: In the healthcare sector, 4D printing with shape-memory alloys can be used to create self-healing medical devices, such as stents, prosthetics, and implants. These devices can adapt to changes in the body, providing a more comfortable and effective treatment for patients.

4. Consumer Products: 4D printing with shape-memory alloys can also be applied to consumer products, such as smart clothing, wearable technology, and household items. These products can adapt to the user’s needs, providing a more personalized and convenient experience.

Challenges and Future Prospects

Despite the numerous advantages of 4D printing with shape-memory alloys, there are still challenges to be addressed. These include the cost of materials, the complexity of the printing process, and the need for further research to optimize the performance of self-repairing devices.

However, as the technology continues to advance, it is expected that these challenges will be overcome. The future of 4D printing with shape-memory alloys looks promising, with the potential to revolutionize various industries and improve the quality of life for people around the world.

In conclusion, the combination of 4D printing technology and shape-memory alloys has paved the way for the development of self-repairing devices. As this field continues to evolve, we can expect to see innovative applications in various industries, leading to a more sustainable and efficient future.