Title: Mini LED Bloom Control: A Comparative Analysis of 576-Zone vs 1152-Zone Grid Tests

Introduction:

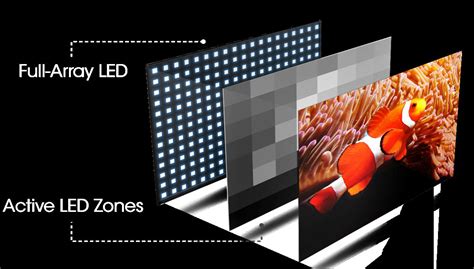

In recent years, Mini LED technology has gained significant attention in the display industry due to its ability to offer high brightness, high contrast, and a wide color gamut. One of the key challenges associated with Mini LED displays is the occurrence of blooming, which can degrade the overall visual quality. To address this issue, manufacturers have developed various bloom control techniques. This article presents a comparative analysis of two popular Mini LED bloom control methods: the 576-zone grid and the 1152-zone grid.

1. Understanding Mini LED Bloom:

Mini LED displays consist of numerous tiny LEDs arranged in a grid pattern. Each LED emits light independently, allowing for precise control of the display’s brightness and color. However, due to the small size of the LEDs and their close proximity, there can be instances where a single LED’s light spills over to adjacent pixels, causing blooming. This phenomenon can lead to a loss of contrast and a degradation in the overall visual experience.

2. 576-Zone Grid Bloom Control:

The 576-zone grid is a popular Mini LED bloom control technique that divides the display into 576 distinct zones. Each zone consists of multiple LEDs that can be independently controlled. The main advantage of this method is its ability to provide precise control over the light output, reducing the chances of blooming. By adjusting the brightness of individual LEDs within a zone, the display can maintain high contrast and minimize blooming effects.

3. 1152-Zone Grid Bloom Control:

The 1152-zone grid takes the concept of zone-based bloom control a step further by dividing the display into 1152 zones. This method offers even finer control over the light output, allowing for more precise adjustments to individual LEDs. The increased number of zones results in a higher level of detail and a reduced likelihood of blooming. However, this also comes with a higher cost and complexity in terms of manufacturing and control algorithms.

4. Comparative Analysis:

When comparing the 576-zone and 1152-zone grid tests, several factors should be considered:

a. Visual Quality: The 1152-zone grid is expected to provide better visual quality due to its finer control over the light output. This can result in reduced blooming and a more consistent contrast ratio across the display.

b. Cost: The 576-zone grid is generally more cost-effective to manufacture and control, as it requires fewer components and simpler algorithms. The 1152-zone grid, on the other hand, can be more expensive and challenging to implement.

c. Application: The choice between the two methods depends on the specific application. For high-end professional displays, the 1152-zone grid may be preferred for its superior visual quality. However, for consumer-grade devices, the 576-zone grid offers a more balanced combination of performance and cost.

Conclusion:

In conclusion, Mini LED bloom control is an essential aspect of achieving high-quality visual experiences. The 576-zone and 1152-zone grid tests represent two distinct approaches to tackle this challenge. While the 1152-zone grid offers superior visual quality, the 576-zone grid provides a more cost-effective solution. Ultimately, the choice between the two methods depends on the specific requirements and constraints of the application.