In the ever-evolving landscape of display technology, the advent of Micro LED has sparked a revolution. This innovative technology promises to redefine the way we interact with screens, offering unparalleled brightness, color accuracy, and energy efficiency. The recent breakthroughs in mass transfer processes have paved the way for the mass production of Micro LED displays. This article outlines the roadmap for the mass production timeline, post these significant advancements.

## Introduction to Micro LED Technology

Micro LED is a display technology that utilizes tiny LED lights, each just a few micrometers in size, to create images. These LEDs are grouped together to form pixels, which are then arranged to create the entire display. The advantages of Micro LED technology include:

– **Higher Brightness**: Micro LEDs can produce significantly brighter images than traditional LED displays.

– **Improved Color Accuracy**: The tiny size of the LEDs allows for more precise control over the color output.

– **Energy Efficiency**: Micro LEDs consume less power than other display technologies, making them more energy-efficient.

– **High Contrast Ratio**: The individual control of each LED pixel ensures a high contrast ratio, resulting in deeper blacks and more vivid colors.

## Mass Transfer Breakthroughs

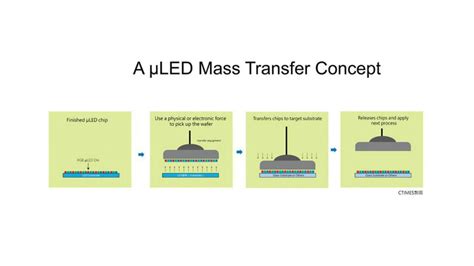

The mass production of Micro LED displays has been a significant challenge due to the complexity of the manufacturing process. However, recent breakthroughs in mass transfer processes have made it possible to produce these displays on a larger scale. Mass transfer refers to the movement of materials during the manufacturing process, and these advancements have improved the efficiency and quality of Micro LED production.

### Key Breakthroughs:

1. **Improved Printing Techniques**: Advanced printing techniques have been developed to place the tiny LEDs accurately on the substrate.

2. **Innovative Bonding Methods**: New bonding methods have been introduced to ensure the stability and longevity of the Micro LED arrays.

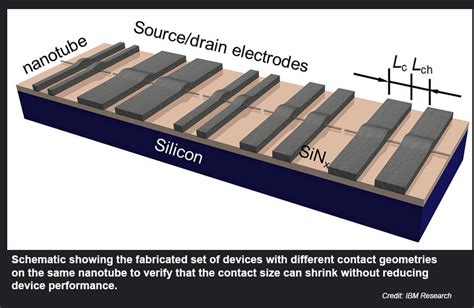

3. **Enhanced Material Science**: The development of new materials has improved the efficiency and durability of Micro LED devices.

## Mass Production Timeline

With the breakthroughs in mass transfer processes, the timeline for mass production of Micro LED displays has been accelerated. Here is a projected roadmap:

### Phase 1: Pilot Production (2023-2024)

– Initial production of Micro LED displays will focus on pilot runs to fine-tune the manufacturing process.

– This phase will also involve testing and validating the quality of the displays.

### Phase 2: Small-Scale Production (2025-2026)

– As the manufacturing process becomes more refined, production will scale up to small batches.

– This phase will see the introduction of Micro LED displays in niche markets, such as professional-grade monitors and high-end smartphones.

### Phase 3: Large-Scale Production (2027-2028)

– With the establishment of efficient manufacturing processes, large-scale production of Micro LED displays will begin.

– This phase will see widespread adoption in consumer electronics, including televisions, laptops, and smartwatches.

### Phase 4: Market Penetration (2029-2030)

– As the cost of production decreases and the quality of Micro LED displays improves, they will become more accessible to the average consumer.

– This phase will mark the widespread adoption of Micro LED technology in various applications.

## Conclusion

The breakthroughs in mass transfer processes have been a game-changer for Micro LED technology. The roadmap for mass production post these advancements is clear, with a timeline that promises to bring Micro LED displays into the mainstream within the next few years. As we move forward, the potential of Micro LED to transform the display industry is immense, offering a new era of visual experiences.